A Passivhaus Music School in Scotland

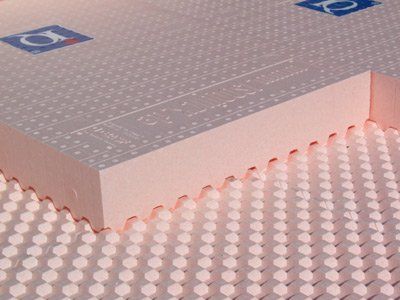

Just before Christmas, we returned to install an Isoquick foundation for Phase 2 of building work at Cnoc Soilleir, a passivhaus music school in South Usit, Scotland.

Almost five years ago in April 2020, we installed an Isoquick foundation for Cnoc Soilleir, a John Renshaw Architects designed music school in South Usit, Scotland that became Passivhaus certified.

Before Christmas last year we returned to the site to install a foundation for phase 2 of the project, a specially designed performance space with room for 200+ people to be seated.

Due to the location of the building and its intended use, this was not a straightforward job by any means.

The two key challenges:

1) In order to create an open plan space with the right acoustics, the ducting and services needed to be laid in Isoquick lined trenches in the floor slab. The design to achieve this required 20 different steps in the slab at 4 different levels.

2) Building in the outer Herbides in Nov/Dec is a challenge in itself. With 60+mph winds everything needed to be held down. On a flat slab it's much less of a problem, but all the steps create lots of opportunities for the wind to get hold of material, hence all the pallets you see in the photos. It may look like a mess but once the rebar and dpm are in it will look very different.

We want to say a big thank you to the team from MacInnes Bros, the contractors on site for their hard work and good humour throughout.

This time, we also met Caroline, the client’s project manager who was kind enough to give us a tour of the finished music school. We don't often get a chance to see the finished job and Caroline was rightly very proud of the building, as are we for our small part in bringing it to life.