By jonathon barnett

•

July 18, 2023

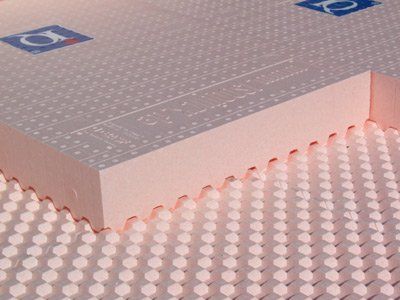

Our customers John and Annie have just finished the groundworks stage of their new family home in Yorkshire, installing an ISOQUICK foundation to the highest specificati on we offer with a 300mm thickness and U Value of 0.09. When finished, the house will be a two-storey, four-bedroom house and will be home to them and their three children aged 5 to 9. At the beginning their project, John and Annie had two priorities: that it must be an eco-house, and it must be comfortable. They first came across the Passivhaus standard when looking into eco building methods and quickly found that they wouldn’t be able to achieve the standard by just renovating their existing house. With professional advice being to demolish and start from scratch that’s exactly what they decided to do. They then found an architect to help them realise their dream, and chose one who is such a Passivhaus advocate it’s the only type of house he now builds. “We chose ISOQUICK as it was recommended by our architect who we trusted. He has used it many times before and found it the best system. It is really important to us that we achieve Passivhaus certification.” For John and Annie, building to Passivhaus Standards is a no-brainer: “Why wouldn't you build a passive house?! We are in a climate crisis and we can't believe there aren't more in the UK and that all new houses don't have to be to this standard.” To fit their budget, they did have to compromise on the house’s size but aren’t worried about it: “We were happy to have a slightly smaller house (because it is more expensive) but for it to be really energy efficient with no cold/drafty spots - so the whole house is useable space. No corners where you don't want to sit therefore no wasted space.” When asked about whether they had any trouble with planning approval or getting their builder on board with a non-traditional foundation, they said: “Planning is always hard but I think they were very welcoming towards certified passive house and gave as much leeway as they could. And from the start, our builder has been willing to work differently and was happy to follow much more detailed drawings and work to higher standards than are common in the industry. They are just as interested in the process as we are and hopefully will be able to do more similar work in future. The use of several specialist subcontractors, like Build Homes Better/ISOQUICK, also helped persuade him he wasn't exposed to too much risk himself.“ Speaking about the ISOQUICK install, John and Annie said “it went really smoothly and easily - it was fantastic to watch. You were very organised and experienced.” Thank you to John and Annie for speaking to us about their experience so far and we expect to follow up with them again in 2024 after their house is finished to find out how it is to live in their ISOQUICK Passivhaus.