How ISOQUICK® is Twice as Effective as Other Insulated Raft Foundations

In comparative analysis ISOQUICK® outperforms its competitors significantly, and by 100% in our most recent analysis. Here's how...

Insulated raft and ring beam foundations, where the insulation is placed under and around the reinforced concrete are common in passive and low energy buildings. They are fast and simple to install and, crucially, they keep the warm inside the building, isolated from the cold ground.

Insulated raft and ring beam foundations offer very good U values irrespective of the size and shape of the building. ISOQUICK® and other insulated raft products perform similarly when comparing U values alone.

However, and here’s the rub: when calculating the U value of a floor, the standard assumes that the floor only extends to the inside of the wall and fails to address variations in thickness of insulation under and at the edge of the concrete slab.

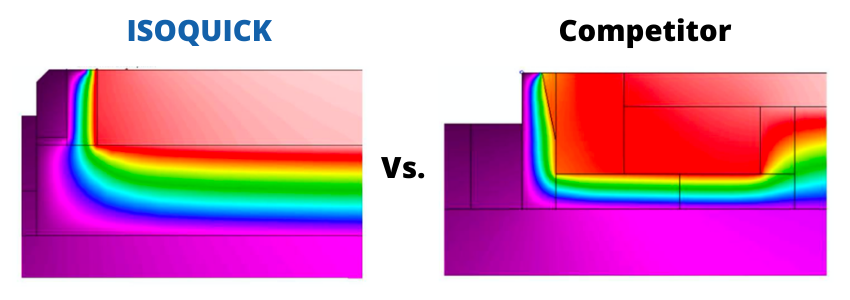

So, to get a more meaningful measure - a true indication of heat loss - it is vital to consider construction details including the edge of the concrete slab, by using thermal modelling.

Thermal modelling shows crucial additional heat loss at the edge of the slab. In comparative analysis ISOQUICK® outperforms its competitors significantly, and by 100% in our most recent analysis.

Why is ISOQUICK® the best insulated raft on the market?

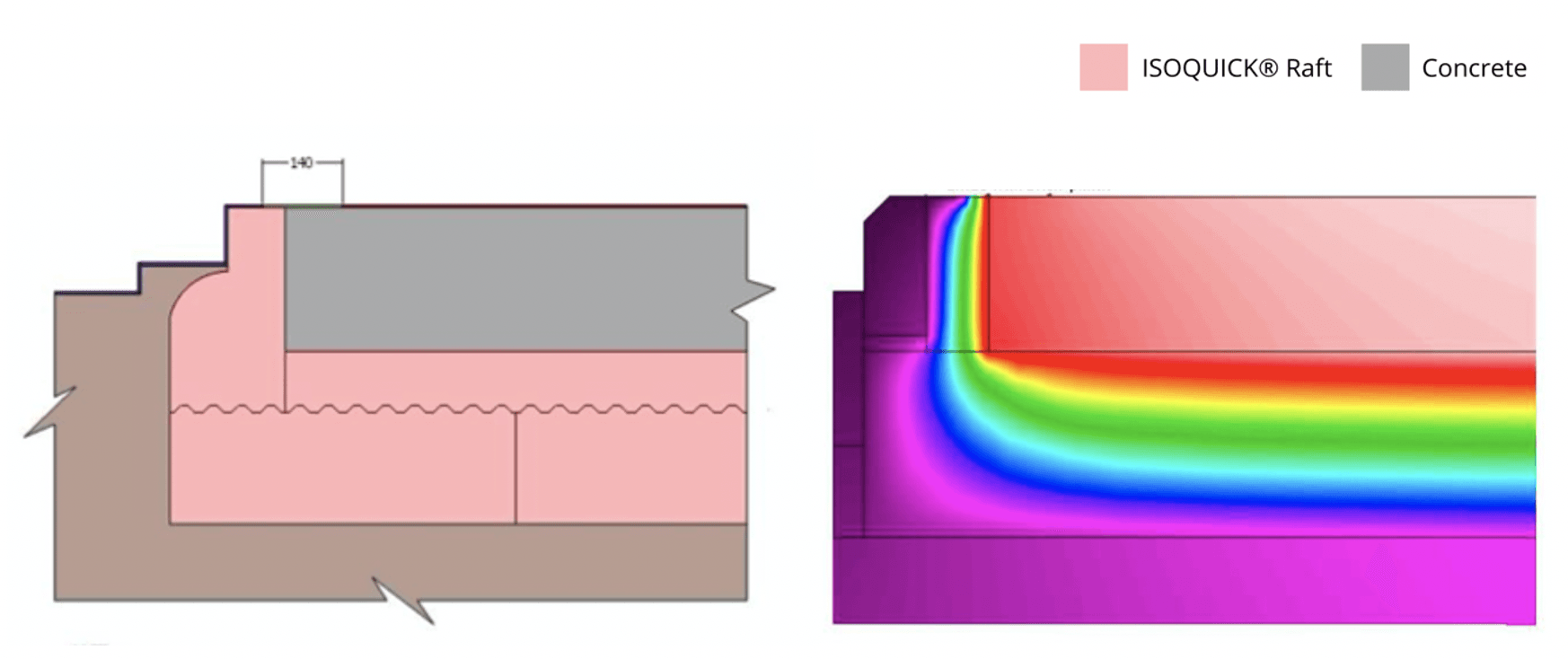

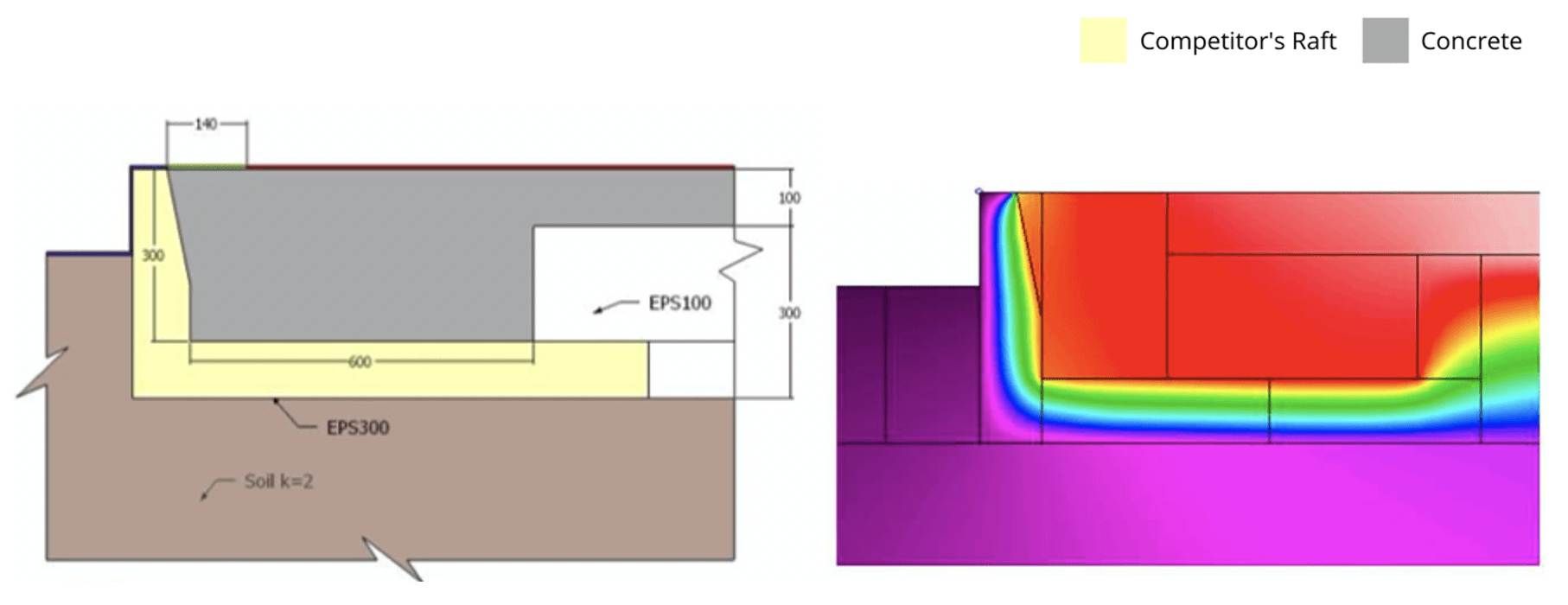

It’s to do with the shape of the concrete and the insulation at the perimeter of the slab under load bearing walls. Both significantly affect Psi value which can often be overlooked in favour of only looking at the U value.

When building a concrete slab with insulation underneath it, the shape of the concrete and insulation at the edge can make a significant impact on the overall amount of heat loss.

When calculating the heat loss from the wall floor junction the nature of the wall, what it is made from and where the insulation is placed can have a significant effect on the resulting Psi value.

ISOQUICK®’s competitors promote designs with a thick beam of concrete around the edge and a thinner concrete slab in the middle. Structurally, this has limitations which we’ll discuss in an upcoming paper, but more importantly here, is it leads to thermal problems.

On paper, the slab designs our competitors promote have good U values. (i.e. low heat loss), which is comparable with ISOQUICK®. And if you only look as far as U values, you may think the products produce the same result.

But reducing the amount of insulation to increase the amount of concrete at the edge can double the amount of heat lost at the edge of the slab.

When looking at an entire floor, this means that ISOQUICK®’s competitors’ slabs can lose 50% more heat than ISOQUICK®, even if the U values are the same. This is shown clearly in the diagrams below.

ISOQUICK® Insulated Raft

Competitor's Insulated Raft

If you would like to see the calculations that underpin this article, please contact our general manager Jonathon Barnett who will be happy to share the relevant technical paper with you.

What is a U value?

A U value is a measure of the heat loss through a square meter of thermal element (e.g. a wall). U values account for the heat loss through thermal elements but not the total heat loss through the fabric.

What are PSI values?

Psi values are a measure of heat loss along a meter of junction between two thermal elements, for example the line between a ground floor and an external wall. This is measured in W/mK. These junctions are known collectively as thermal bridging and can be an overlooked source of heat loss.

About ISOQUICK®

Described by the Passivhaus Institute as "The Optimal Thermal Bridge Free Foundation Solution", ISOQUICK® provides both an effective and inexpensive insulating foundation that can be easily adapted for any new-build residential or commercial project – be it a low-energy, passive, net-zero-energy or energy-plus house.

ISOQUICK®’s insulating foundation is based on the concept of raft foundations using a semi-rigid foundation slab.

The modules are prefabricated and assembled on site. Any offcuts due to forming drainage and duct entries is recycled back at the factory. This eliminates waste. By contrast, some of our competitors deliver much more material to site to accommodate shortcuts in design. The consequent additional cutting on site leaves considerable waste for the client to remove. Currently there are no public facilities to recycle this waste and therefore it goes to landfill.

Our team is known for going above and beyond when it comes to supporting our customers. If you have any site specific questions, would like some advice or want a quote please don’t hesitate to contact Jonathon@buildhomesbetter.co.uk